GB-SPZ1400-1750PT

GREEN BUILDING MACHINERY

The GB-SPZ1400-1750PT represents state-of-the-art technology in fully automatic Expandable Polystyrene (EPS) foam molding equipment. Designed to meet the core demands of modern EPS packaging and molding plants for high efficiency, low energy consumption, user-friendly operation, and maintenance safety, this model integrates a precise PLC control system, an intuitive touchscreen HMI, a robust and stable hydraulic drive system, and optimized thermal processes (steam heating, water cooling, and vacuum cooling). It achieves fully automated, precise control throughout

the entire production cycle, from material feeding to finished product ejection. Its outstanding performance and user-centric design make it the ideal choice for boosting production efficiency and reducing operational costs.

1. Robust & Stable Hydraulic Drive System:

High-Power Hydraulic Motor + Reinforced Machine Body: Utilizes a high-power hydraulic power unit (standard 11kW oil pump, superior to the common 7.5kW) coupled with a high-flow pump, delivering abundant power.

Ultra-High Speed & Stable Operation: The optimized hydraulic system design, combined with a unique double-hinged frame structure, ensures exceptionally smooth and vibration-free operation even at high mold closing/opening speeds of up to 260mm/s. Compared to conventional machines, this significantly saves 3-4 seconds per cycle, dramatically increasing production efficiency.

Innovative Product Removal & Structural Design: Features an automatic conveyor belt to swiftly remove molded products from the work area. This design allows for reduced machine leg height, working in tandem with the stable double-hinged frame to guarantee overall rigidity and stability during high-speed operation.

2. Accurate, Stable & Efficient Steam Heating System:

High-Flow Steam Supply: Equipped with large-diameter steam piping (main pressure reducing valve: Japan brand DN100), with DN65-DN80 steam connections for each mold side, ensuring rapid and ample steam supply.

Intelligent & Precise Temperature Control: Employs SMC (USA) PID Proportional Control Valves and Balance Valves at critical points for accurate and stable steam pressure regulation. This not only guarantees uniform and repeatable heating – essential for producing high-quality, consistent EPS products – but also effectively reduces steam energy consumption and shortens heating cycle time

3. High-Efficiency Vacuum Cooling System:

Dual-Stage Cooling Design: The machine features a high-efficiency vacuum tank with an integrated top-mounted water spray system (water cooling). An additional stainless steel (S.S.) heat exchanger is installed inside the tank, creating a unique "dual-stage cooling" mechanism.

Significantly Enhanced Cooling Efficiency: This design rapidly condenses large volumes of hot vapor, significantly improving vacuum suction efficiency and consequently drastically reducing cooling time, further boosting the overall production cycle.

4. Intelligent Control System & Operator/Maintenance Focus:

Fully Digitalized Control: Based on an advanced PLC controller and a large touchscreen HMI, all process parameters (pressure, time, temperature, etc.) can be intuitively set and monitored via the screen.

Precise Process Execution: Key actions (such as filling, heating, and demolding) are precisely controlled via SMC digital PID valves, completely replacing traditional mechanical manual valves, ensuring process consistency and repeatability.

Convenient Maintenance & Safety: Human-centric design is evident in maintenance accessibility: the control cabinet features a recessed installation (positioned at ground level), and spacious maintenance platforms surround the machine and provide access to the top, greatly facilitating daily inspections and servicing while enhancing operator safety.

The GB-SPZ1400-1750PT Full-Automatic Foam Forming Machine is the ideal equipment for:

EPS Packaging Products (protective packaging for appliances, electronics, fragile goods, food, etc.)

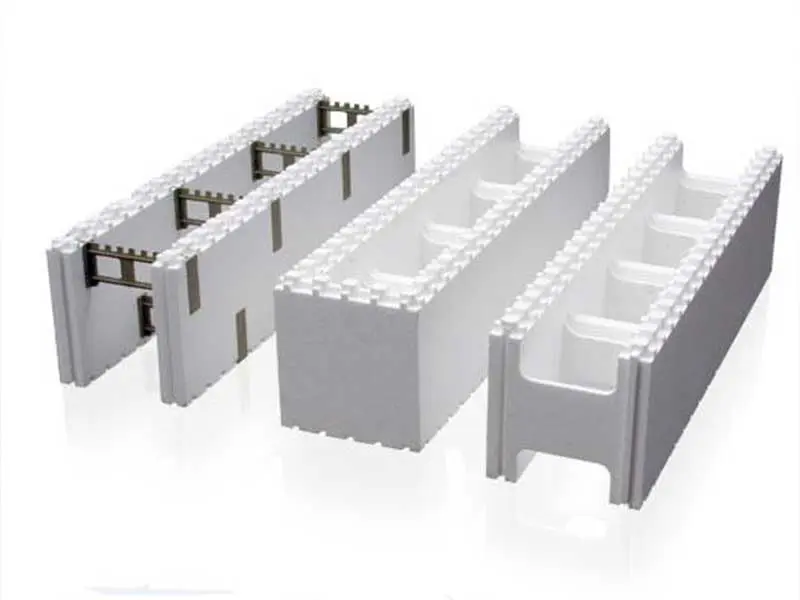

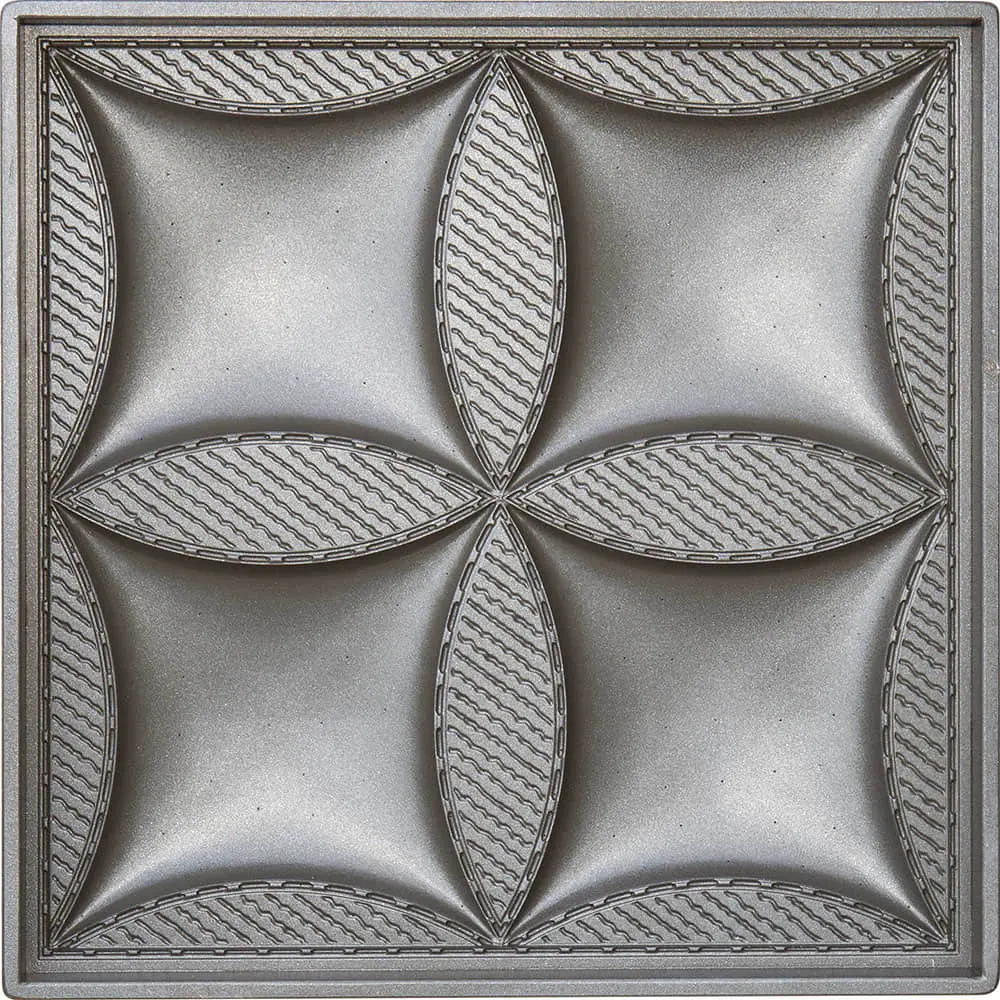

EPS Building Insulation Materials (blocks, decorative moldings, etc.)

EPS Industrial Component Liners & Cushioning

Other fields requiring high-quality, high-efficiency EPS molded products.

The GB-SPZ1400-1750PT Full-Automatic Foam Forming Machine sets a performance benchmark in the EPS molding industry with its robust and stable mechanical structure, powerful high-speed hydraulic system, precise and efficient steam heating, innovative rapid vacuum cooling, and intelligent, safety-focused operation and maintenance design. It significantly enhances molding speed and product quality, effectively reduces steam energy consumption and unit production costs. Moreover, its exceptional ergonomic design ensures operational ease and maintenance safety. For EPS foam packaging and molding plants pursuing high output, low energy usage, and high reliability, the GB-SPZ1400-1750PT is undoubtedly the premier choice for gaining a competitive edge.

| Mould Dimension | mm | 1400×1200 | 1600×1350 | 1750×1450 | |

| Product Dimension | mm | 1200×1000 ×330 | 1400×1100 ×330 | 1550×1200 ×330 | |

| Minimum Mould Thickness | mm | 220 | 220 | 220 | |

| Stroke | mm | 210-1410 | 210-1410 | 210-1410 | |

| Speed | mm/sec | 210 | 210 | 210 | |

| Steam | Entry | / | DN100 | DN100 | |

| Consumption | Kg/cycle | 6-8 | 7-9 | 7-10 | |

| Pressure | MPa | 0.6 | 0.6 | 0.6 | |

| Cooling water | Entry | / | DN65 | DN65 | DN65 |

| Consumption | Kg/cycle | 55-150 | 55-180 | 60-190 | |

| Pressure | MPa | 0.4 | 0.4 | 0.4 | |

| Compressed air | Entry | / | DN50 | DN50 | DN50 |

| Consumption | m3/cycle | 1.5 | 1.5 | 1.4 | |

| Pressure | MPa | 0.6 | 0.6 | 0.6 | |

| Vacuum Pump Capacity | m3/h | 230 | 280 | 280 | |

| Connected Load | Kw | 12.5 | 16.5 | 16.5 | |

| Overall Dimension | mm | 4600×2140 ×3100 | 5000×2300×3400 | 5000×2450×3500 | |

| Machine Weight | Kg | 5700 | 7000 | 7500 | |

| Cycle time/Packaging products | S | 50-90 | 70-100 | 70-110 | |

| items | Machine specification | |

| Anti-corrosiontreatment | Machine body | Welded-heating treatment-sandblast-Zink coating-painting |

| All steam, water ,drainage pipe | Hot-zink coating | |

| Electrical element | Touch screen PLC | Mitsubishi PLC, |

| Relay, contactor | Schneider electric | |

| Approx-sensor | Autonics | |

| Air Solenoid Valve | Burket ,Germany | |

| Steam | Main DN100 | |

| DN65 for fixed and movable size | ||

| With by-pass steam pipe, DN40 | ||

| Electrical proportional steam pressure setting in touch screen | ||

| GP1000 PRV | ||

| Cooling water | DN65 | |

| Mold cooling &vacuum cooling | ||

| Compressed air de-mould | Multi-selection mold | |

| M1 &M1 , electrical proportional pressure control | ||

| Filling hopper | 2-Vertical type | |

| 44-1″ outlet | ||

| Pressurized tank filling | ||

| Fast connector equipped | ||

| Blowing filling pressure adjustable by mechanical proportional control | ||

| High machine leg | 1.5 meter higher machine leg , Hot GV |

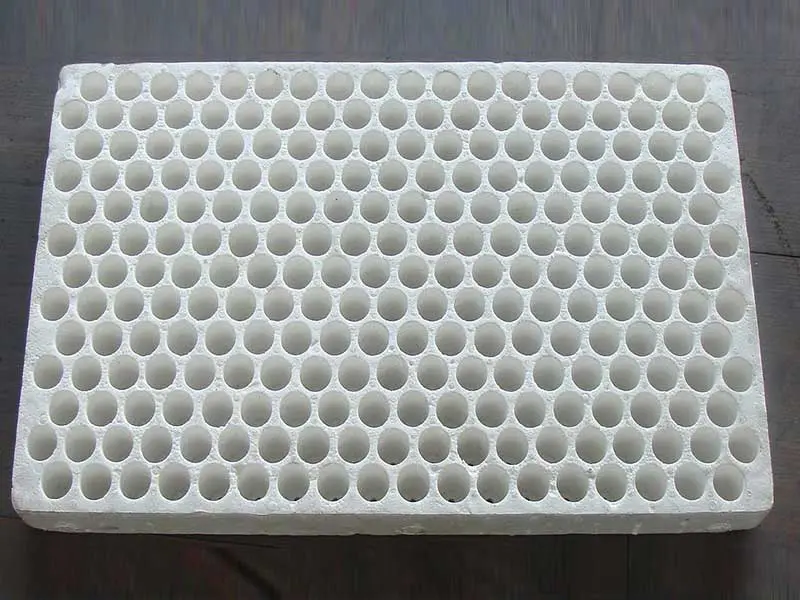

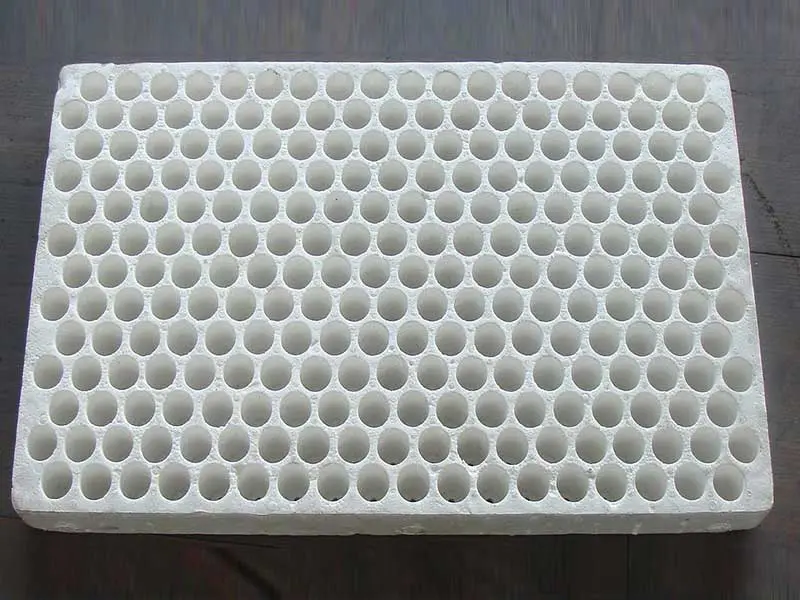

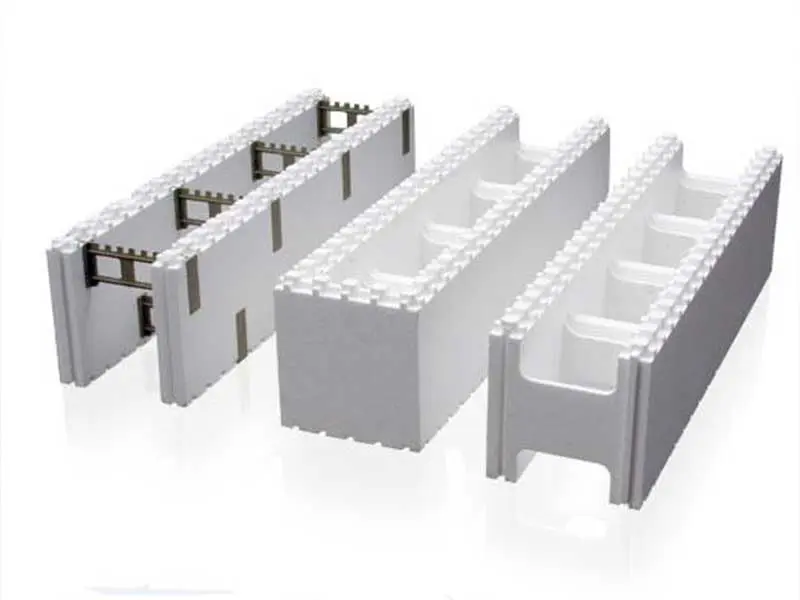

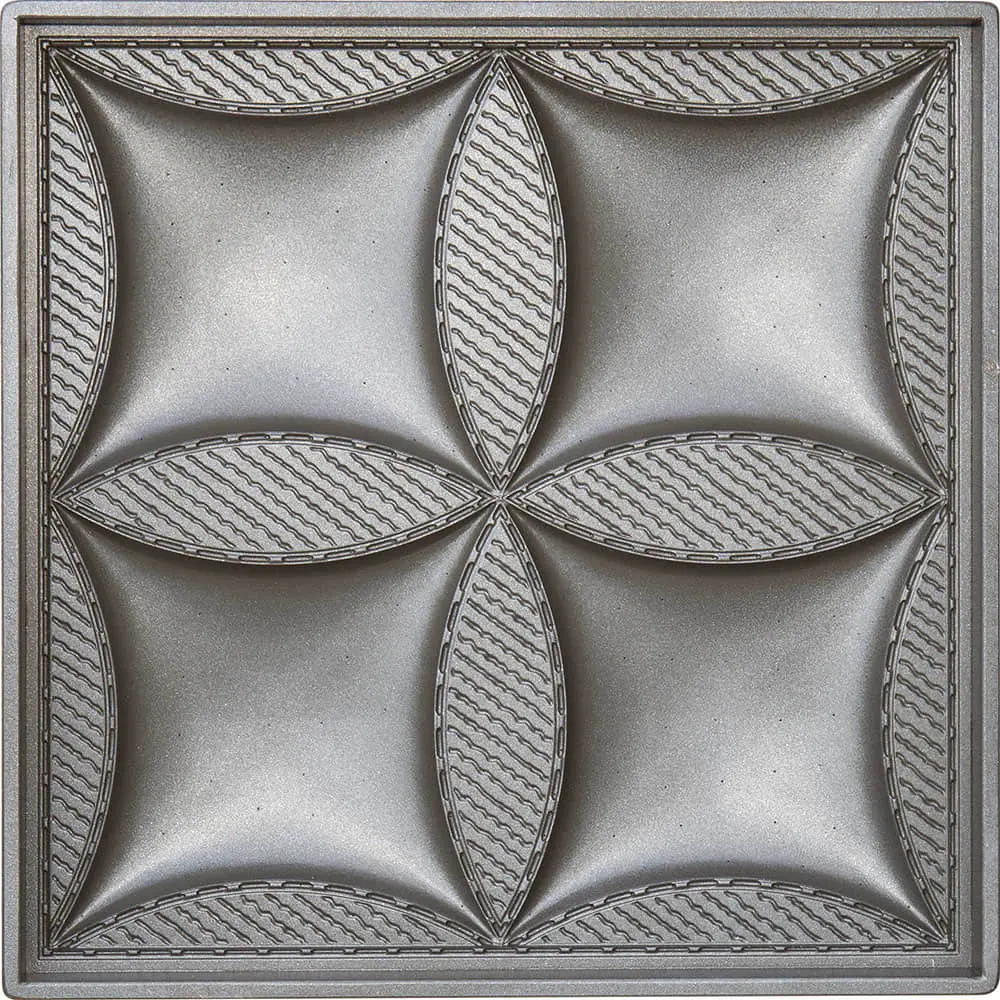

Our Moulds

EPS is commonly used for packaging medical,fruit,vegetables and electrical, insulation panels for building. With the good quality,it can be expand 40 times the volume of the original polystyrene bead.

The GB-SPZ1400-1750PT represents state-of-the-art technology in fully automatic Expandable Polystyrene (EPS) foam molding equipment. Designed to meet the core demands of modern EPS packaging and molding plants for high efficiency, low energy consumption, user-friendly operation, and maintenance safety, this model integrates a precise PLC control system, an intuitive touchscreen HMI, a robust and stable hydraulic drive system, and optimized thermal processes (steam heating, water cooling, and vacuum cooling). It achieves fully automated, precise control throughout

the entire production cycle, from material feeding to finished product ejection. Its outstanding performance and user-centric design make it the ideal choice for boosting production efficiency and reducing operational costs.

1. Robust & Stable Hydraulic Drive System:

High-Power Hydraulic Motor + Reinforced Machine Body: Utilizes a high-power hydraulic power unit (standard 11kW oil pump, superior to the common 7.5kW) coupled with a high-flow pump, delivering abundant power.

Ultra-High Speed & Stable Operation: The optimized hydraulic system design, combined with a unique double-hinged frame structure, ensures exceptionally smooth and vibration-free operation even at high mold closing/opening speeds of up to 260mm/s. Compared to conventional machines, this significantly saves 3-4 seconds per cycle, dramatically increasing production efficiency.

Innovative Product Removal & Structural Design: Features an automatic conveyor belt to swiftly remove molded products from the work area. This design allows for reduced machine leg height, working in tandem with the stable double-hinged frame to guarantee overall rigidity and stability during high-speed operation.

2. Accurate, Stable & Efficient Steam Heating System:

High-Flow Steam Supply: Equipped with large-diameter steam piping (main pressure reducing valve: Japan brand DN100), with DN65-DN80 steam connections for each mold side, ensuring rapid and ample steam supply.

Intelligent & Precise Temperature Control: Employs SMC (USA) PID Proportional Control Valves and Balance Valves at critical points for accurate and stable steam pressure regulation. This not only guarantees uniform and repeatable heating – essential for producing high-quality, consistent EPS products – but also effectively reduces steam energy consumption and shortens heating cycle time

3. High-Efficiency Vacuum Cooling System:

Dual-Stage Cooling Design: The machine features a high-efficiency vacuum tank with an integrated top-mounted water spray system (water cooling). An additional stainless steel (S.S.) heat exchanger is installed inside the tank, creating a unique "dual-stage cooling" mechanism.

Significantly Enhanced Cooling Efficiency: This design rapidly condenses large volumes of hot vapor, significantly improving vacuum suction efficiency and consequently drastically reducing cooling time, further boosting the overall production cycle.

4. Intelligent Control System & Operator/Maintenance Focus:

Fully Digitalized Control: Based on an advanced PLC controller and a large touchscreen HMI, all process parameters (pressure, time, temperature, etc.) can be intuitively set and monitored via the screen.

Precise Process Execution: Key actions (such as filling, heating, and demolding) are precisely controlled via SMC digital PID valves, completely replacing traditional mechanical manual valves, ensuring process consistency and repeatability.

Convenient Maintenance & Safety: Human-centric design is evident in maintenance accessibility: the control cabinet features a recessed installation (positioned at ground level), and spacious maintenance platforms surround the machine and provide access to the top, greatly facilitating daily inspections and servicing while enhancing operator safety.

The GB-SPZ1400-1750PT Full-Automatic Foam Forming Machine is the ideal equipment for:

EPS Packaging Products (protective packaging for appliances, electronics, fragile goods, food, etc.)

EPS Building Insulation Materials (blocks, decorative moldings, etc.)

EPS Industrial Component Liners & Cushioning

Other fields requiring high-quality, high-efficiency EPS molded products.

The GB-SPZ1400-1750PT Full-Automatic Foam Forming Machine sets a performance benchmark in the EPS molding industry with its robust and stable mechanical structure, powerful high-speed hydraulic system, precise and efficient steam heating, innovative rapid vacuum cooling, and intelligent, safety-focused operation and maintenance design. It significantly enhances molding speed and product quality, effectively reduces steam energy consumption and unit production costs. Moreover, its exceptional ergonomic design ensures operational ease and maintenance safety. For EPS foam packaging and molding plants pursuing high output, low energy usage, and high reliability, the GB-SPZ1400-1750PT is undoubtedly the premier choice for gaining a competitive edge.

| Mould Dimension | mm | 1400×1200 | 1600×1350 | 1750×1450 | |

| Product Dimension | mm | 1200×1000 ×330 | 1400×1100 ×330 | 1550×1200 ×330 | |

| Minimum Mould Thickness | mm | 220 | 220 | 220 | |

| Stroke | mm | 210-1410 | 210-1410 | 210-1410 | |

| Speed | mm/sec | 210 | 210 | 210 | |

| Steam | Entry | / | DN100 | DN100 | |

| Consumption | Kg/cycle | 6-8 | 7-9 | 7-10 | |

| Pressure | MPa | 0.6 | 0.6 | 0.6 | |

| Cooling water | Entry | / | DN65 | DN65 | DN65 |

| Consumption | Kg/cycle | 55-150 | 55-180 | 60-190 | |

| Pressure | MPa | 0.4 | 0.4 | 0.4 | |

| Compressed air | Entry | / | DN50 | DN50 | DN50 |

| Consumption | m3/cycle | 1.5 | 1.5 | 1.4 | |

| Pressure | MPa | 0.6 | 0.6 | 0.6 | |

| Vacuum Pump Capacity | m3/h | 230 | 280 | 280 | |

| Connected Load | Kw | 12.5 | 16.5 | 16.5 | |

| Overall Dimension | mm | 4600×2140 ×3100 | 5000×2300×3400 | 5000×2450×3500 | |

| Machine Weight | Kg | 5700 | 7000 | 7500 | |

| Cycle time/Packaging products | S | 50-90 | 70-100 | 70-110 | |

| items | Machine specification | |

| Anti-corrosiontreatment | Machine body | Welded-heating treatment-sandblast-Zink coating-painting |

| All steam, water ,drainage pipe | Hot-zink coating | |

| Electrical element | Touch screen PLC | Mitsubishi PLC, |

| Relay, contactor | Schneider electric | |

| Approx-sensor | Autonics | |

| Air Solenoid Valve | Burket ,Germany | |

| Steam | Main DN100 | |

| DN65 for fixed and movable size | ||

| With by-pass steam pipe, DN40 | ||

| Electrical proportional steam pressure setting in touch screen | ||

| GP1000 PRV | ||

| Cooling water | DN65 | |

| Mold cooling &vacuum cooling | ||

| Compressed air de-mould | Multi-selection mold | |

| M1 &M1 , electrical proportional pressure control | ||

| Filling hopper | 2-Vertical type | |

| 44-1″ outlet | ||

| Pressurized tank filling | ||

| Fast connector equipped | ||

| Blowing filling pressure adjustable by mechanical proportional control | ||

| High machine leg | 1.5 meter higher machine leg , Hot GV |

Our Moulds

EPS is commonly used for packaging medical,fruit,vegetables and electrical, insulation panels for building. With the good quality,it can be expand 40 times the volume of the original polystyrene bead.